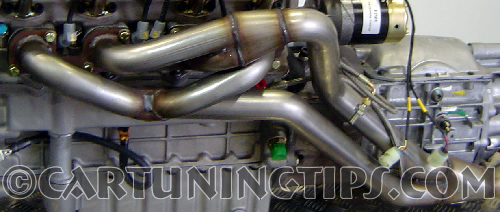

Engines burn fuel and need to expel the combustion materials in the most efficient manner possible. The exhaust is the route these take from the engine to the back of the car but there are many considerations that need to be taken into account to ensure this happens in the best way possible. It is essential to get the flow rate just right, too low a flow rate and the power band will suffer.  Manifolds or headers, are what joins the engine to the exhaust system. Most usual engines have 4 ports (6 if it is a 6 cylinder etc) and these usually end up as one or two exhaust pipes at the rear of the car. Internally the exhaust pipes should be as smooth as possible, any rough areas or seams will cause turbulence and this restricts the flow of the exhaust and power will be lost. It is usual that OEM manifolds or headers are cast in iron and this leaves a pitted surface with deep cast seams left in the metal from the mould.

Manifolds or headers, are what joins the engine to the exhaust system. Most usual engines have 4 ports (6 if it is a 6 cylinder etc) and these usually end up as one or two exhaust pipes at the rear of the car. Internally the exhaust pipes should be as smooth as possible, any rough areas or seams will cause turbulence and this restricts the flow of the exhaust and power will be lost. It is usual that OEM manifolds or headers are cast in iron and this leaves a pitted surface with deep cast seams left in the metal from the mould.

Exhaust flow rates are critical, a fast flow rate associated with a narrow exhaust will aid scavenging but can restrict air flow capacity, so there is a compromise to be had for optimum flow where you want the power band to be.

A stainless steel system will usually make for a better flow over cast iron as the bends are precisely machined and the joins are generally much smoother. If you want to improve your standard cast header the a grinding wheel on a flexible arm will allow you to get right in there and then finish it off with a polishing wheel. Smooth out the rough internals and try as best you can to remove any cast seams. Aim also to reduce the internal angles by grinding away the excess metal.

The down pipe usually has a flexible coupling to inhibit vibration from the engine affecting the exhaust mountings and keeps the car a bit quieter. Again this should be internally as smooth as possible and any welded seams should be smoothed down but as these are generally quite short is not essential to spend much time on these. Then in the last 20 years or so we saw the introduction of Catalysts which forces the exhaust gases to react and it reduces the harmfull emissions of the engine.

A free flowing sports cat can noticeably increase the power output of the engine by around 4% on average. The other option is to decat, (Removing the catalyst) altogether but this can cause issues and faults with some engine management systems and will not usually yield much of a noticeable power gain over a sports catalyst.

Overall gains for a sport cat or decat installation are 2-6 bhp.

Main exhaust pipe runs the length of the car to take the fumes away from the occupants although we have seen some side exit exhaust that work quite well. This will need to bend around the contours underneath the car so it would be best to minimise the bends as much as possible. Generally though the exhaust has to go around the rear axle so bends cannot be avoided. When you are joining pipes of different diameters you should always make the join a cone shape to aid the smooth transition avoiding turbulence. Stainless steel is a good long life material provided it is bent to shape rather than cut and welded.

Sometimes cars have an expansion box before the final silencer to help muffle the noise a little, this is also referred to as a resonator. In most set ups the exhaust gasses are diverted around a series of baffles which contain a sound deadening material. The more freely the exhaust gases can flow through this the better. In performance cars you really want a straight through silencer so the exhaust flow rates are not impeded too much.

The larger the bore of the silencer the lower the tone of the exhaust. Twin pipes and slashes do little to alter the flow of gasses and are primarily there for aesthetic purposes but the larger the volume of these pipes the greater the air flow.

Beware that having a large exhaust can reduce the torque of the engine and leave it with no low down pulling power due to the lower flow rate from the larger bore. The diameter of the exhaust is a precise calculation and takes into account the engines volumetric efficiency. Ideally you want less back pressure as the engine revs increases and to this end some manufacturers have fitted a valve to the exhaust which opens to increase the flow rate of an engine at high rpm.